Be Energy : Solutions Batteries Plus

LEAD-ACID BATTERIES

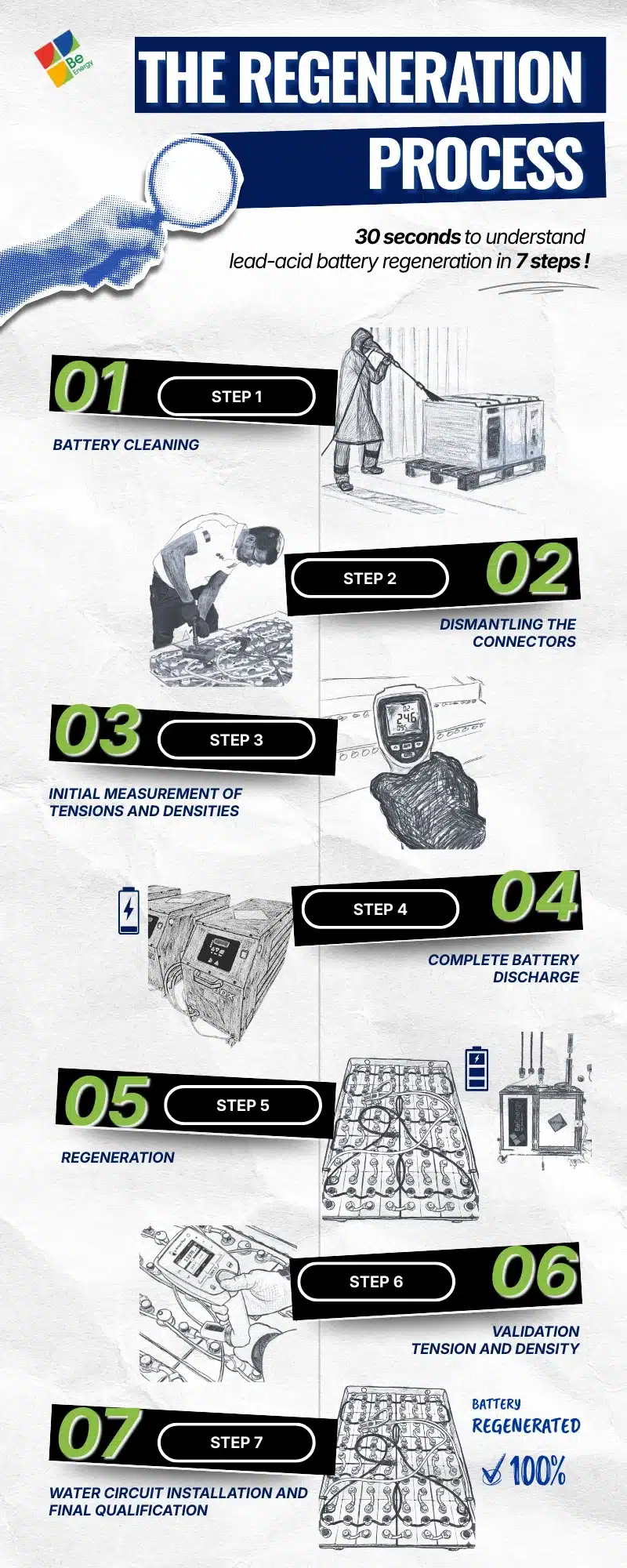

Lead-acid battery regeneration process: the 7 steps

Lead-acid battery regeneration is a controlled electrochemical process that restores batteries that have become unusable due to sulfation. The lead-acid battery regeneration process acts directly on the cause of capacity loss: the crystallization of lead sulfate on the internal plates.

This treatment is carried out in a workshop, according to a specific protocol, using specialized equipment.

Why does a lead-acid battery become sulfated?

When a battery discharges, the positive and negative plates turn into lead sulfate. If the battery is not recharged quickly, this sulfate crystallizes.

This crystallization prevents recharging with a traditional charger. The battery then appears to be out of service, even though its internal components are still functional.

The lead battery regeneration process breaks down this crystallization.

Regeneration is based on sending high-power, precisely controlled electrical pulses.

These pulses will:

-

break up the lead sulfate crystals,

-

return the sulfate to solution in the electrolyte,

-

restore acidity,

-

chemically reactivate the plates.

A conventional charger cannot perform this operation.

The 7 steps of lead battery regeneration

1. Complete battery cleaning

The battery undergoes a thorough cleaning process: removal of acid deposits, conductive dust, surface oxidation, and operating residues.

This cleaning also allows for a detailed visual inspection of the condition of the cells, terminals, and sealing areas.

It also aims to restore the battery to a clean appearance, consistent with professional recommissioning.

The goal : Avoid any measurement pollution or parasitic electrical leakage paths, guarantee a neutral environment for testing, and ensure a visual presentation consistent with a battery that is ready to be reused.

2. Removing the connectors

The bridges, terminals, cables, and connecting elements are removed in order to electrically isolate the battery. The battery is thus removed from all operating circuits.

The goal : Prevent any external electrical interaction during discharge and pulse cycles, which would distort the treatment.

3. Measurement of initial stresses and densities

Each element is measured individually :

-

voltage per cell,

-

electrolyte density,

-

homogeneity between elements,

-

identification of significant discrepancies.

These measurements constitute the initial mapping of the internal state of the battery.

The goal : Establish an objective baseline for accurately measuring the effect of regeneration.

4. Controlled total discharge

The battery is subjected to a controlled and instrumented discharge in order to simulate an operational discharge and record the electrical behavior curves before treatment.

This acquisition allows us to observe:

-

maintaining voltage under load,

-

the speed of collapse,

-

imbalances between elements,

-

the overall electrical signature of the sulfated battery.

This data serves as a reference for managing and analyzing regeneration.

The goal : Obtain the initial characteristic curves essential for accurately monitoring the effectiveness of the regeneration process.

5. Regeneration by electrical pulses

The battery is connected to the regenerator. Sequences of high-energy electrical pulses, with controlled frequency and amplitude, are applied for a period ranging from 24 to 96 hours.

These impulses cause:

-

the mechanical fragmentation of sulfate crystals,

-

their redissolution in the electrolyte,

-

the gradual restoration of acidity,

-

the reactivation of the active surfaces of the plates.

The goal :Treating the crystal structure of sulfate, which no conventional charge can achieve.

6. Validation of final stresses and densities

The same steps as in step 3 are performed :

-

voltage per cell,

-

electrolyte density,

-

overall homogeneity.

The comparison highlights the electrochemical restoration achieved.

The goal : Objectively validate the effectiveness of the treatment and ensure that balance has been restored between the elements.

7. Installation of the water circuit and recommissioning

Electrolyte levels are adjusted if necessary. The water circuit is reinstalled. The connectors are reassembled.

The battery is then ready to be put back into service.

The goal : Ensure that the remanufactured battery is returned to optimal and sustainable operating conditions.

These seven steps constitute an inseparable sequence of operations.

Each step prepares for the next and contributes to the measurable electrochemical restoration of the battery.

The process of regenerating a lead-acid battery is not based on simple charging, but on an instrumented methodology, comparative readings, and the application of appropriate electrical pulses.

It is this rigorous execution that makes it possible to obtain reproducible results in the workshop.

Regeneration then becomes a controlled technical process, based on measurements, curves, and objective parameters.

Extend your battery life and cut your costs

Before replacing your batteries, it is essential to know whether they can still be regenerated. Our diagnosis is based on our technical expertise and industrial protocol, guaranteeing a reliable and accurate assessment.

Thanks to this check, you can avoid unnecessary purchases, extend the life of your batteries, and reduce your costs, while also helping the environment.

Don’t let your batteries lose their potential: have them diagnosed today!

Ready to audit the potential of your deposit?

Contact our experts for a personalized analysis of your fleet. Together, let’s move from waste management to sustainable asset management.