Be Energy : Solutions Batteries Plus

NIMH BATTERIES

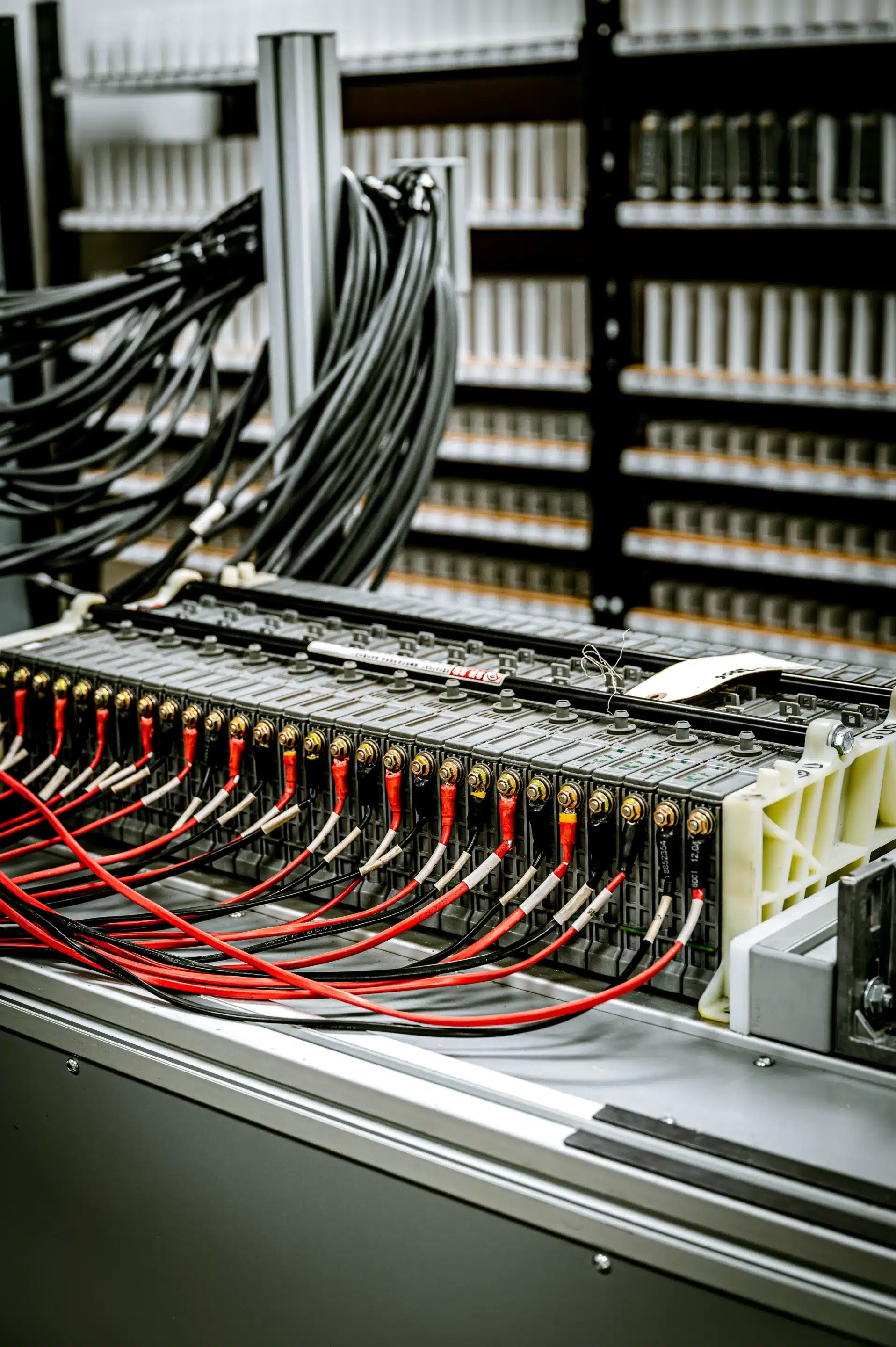

NiMH battery with prismatic modules

In a self-charging hybrid vehicle, the battery is not used to travel dozens of kilometers in pure electric mode. It acts as an energy buffer: it absorbs energy during braking, releases it during acceleration, and continuously assists the combustion engine.

To fulfill this demanding role, many manufacturers have adopted the prismatic NiMH (nickel-metal hydride) module. This format has become the standard among several hybrid leaders due to its robustness, chemical stability, and ability to withstand very frequent cycles.

Understanding how it works makes it easier to anticipate its aging and avoid unnecessary premature replacement.

What is a prismatic module?

A prismatic NiMH module is a rigid rectangular casing containing several Nickel-Metal Hydride cells assembled in series.

Unlike the old separate cylindrical cells, here:

- the elements are grouped together in a compact structure,

- the internal connections are optimized,

- integration into the pack is denser and more structured.

A hybrid pack consists of a set of these modules (often between 20 and 40 depending on the model). Each module contributes to the overall voltage and energy balance of the system.

This modular architecture is essential: it allows localized drifts to be identified precisely rather than considering the battery as an indivisible block.

Why is prismatic NiMH suitable for hybrids?

NiMH has characteristics that are particularly relevant for HEV use:

Tolerance to rapid cycles

A hybrid undergoes thousands of microcycles.

NiMH batteries withstand these rapid variations in charge and discharge well.

Thermal stability

Compared to other chemistries, NiMH is known for its stability and resistance to sudden drifts.

Robustness in partial range

Hybrid batteries generally operate between 20% and 80% charge.

NiMH is particularly well suited to this constant intermediate range operation.

The technical limitations of prismatic NiMH batteries

Despite its robustness, the prismatic NiMH module is not without its limitations, particularly in terms of heat.

1. Internal heat concentration

The rectangular geometry optimizes integration but limits the natural exchange surface. During repeated use—city driving, high outside temperatures—heat can build up in the center of the module.

Over time, this leads to:

- an increase in internal resistance,

- a gradual decrease in capacity,

- faster aging of certain modules.

2. Heterogeneous aging in the pack

Modules located in the center of the pack are often more exposed to heat accumulation than those on the periphery. This difference creates:

- voltage differences between modules,

- an overall imbalance,

- preventive intervention by the BMS.

The hybrid system then reduces the available power to protect the battery.

3. Memory effect and electrochemical drift

Even though modern NiMH batteries are less sensitive than earlier generations, a drift phenomenon can occur over time:

- reduction in usable capacity,

- voltage that drops more quickly under load,

- less effective electric assistance.

This is not necessarily a total failure, but rather a partial weakening.

Common symptoms of a prismatic NiMH battery pack experiencing fatigue

- Less noticeable electric assistance

- Greater demand on the combustion engine

- Increased fuel consumption

- Hybrid battery warning light

- More frequent battery ventilation

In most cases, only certain modules are actually weakened.

NiMH and regeneration: The winning and safe alternative

Over time, NiMH batteries experience an increase in internal resistance, which reduces their autonomy. Our industrial process does more than just recharge the battery; it thoroughly restores it.

Our technical protocol :

-

Module-by-module diagnosis: Individual analysis of each module to identify faulty modules.

-

Desulfation treatment: Use of our equipment to regenerate the internal chemistry.

-

Balancing and testing: Validation of load capacity and discharge power under stress, as well as pack stability (voltage deviations).

-

SOH certification: Qualification of modules by capacity grade and provision of a comprehensive health report for the pack.

The economic advantage: Regeneration generally costs 50% to 80% less than a new battery, while giving your equipment a second life.

A commitment to the circular economy

Replacing a hybrid battery is a significant expense.

In many cases, targeted intervention can:

- extend the vehicle’s service life,

- restore electric assistance,

- significantly reduce the cost compared to a new battery.

Prismatic NiMH technology is designed to last.

It simply requires rigorous diagnosis and intervention adapted to its thermal and electrochemical constraints.

Waste reduction

Extending the life of valuable metals such as nickel.

Financial savings

Regenerating your battery costs on average

50% less than buying a new one.

CO2 emissions

Up to 80% less CO2 compared to manufacturing a new battery.

Preservation of natural resources

Focus on repair rather than extraction of new resources.

Is your hybrid vehicle showing signs of weakness?

A loss of assistance or a battery warning light does not necessarily mean that the battery pack has reached the end of its life.

A precise technical diagnosis can determine its actual condition.

Request an analysis of your prismatic NiMH hybrid battery.